Frequency Conversion Single Puller

- ruijia

- jiangsu

- 20 days

- 500 sets/month

We are a professional supplier of aluminum extrusion line,We can make a whole program for you, only need you to provide the following information:

1. Drawing

2. Product material requirements

3. Product Usage

4. output

Please contact me immediately.

product description:

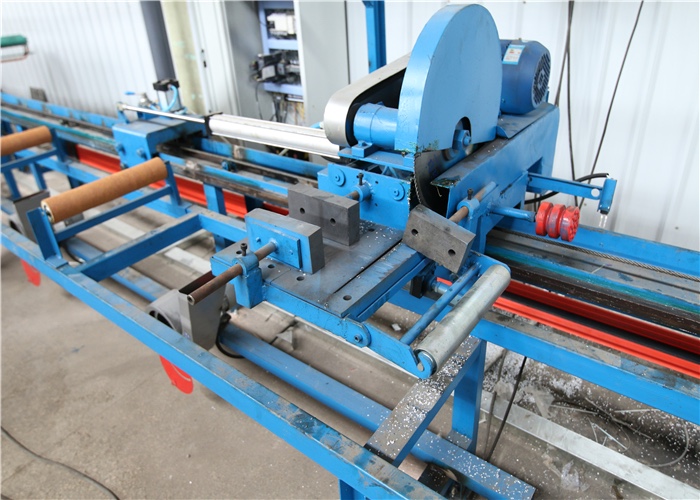

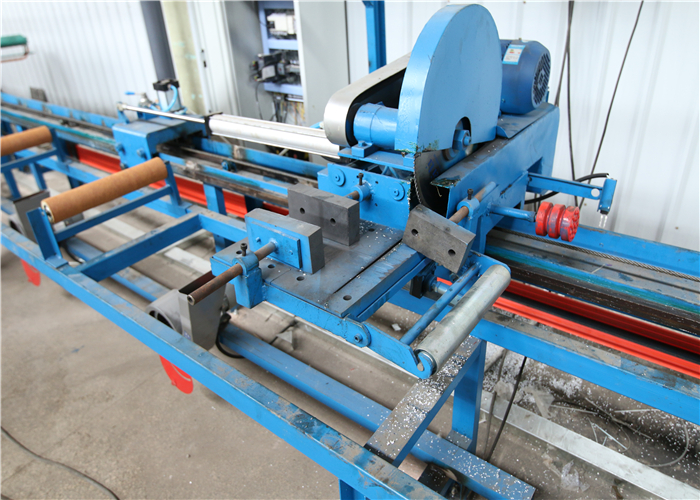

The tractor is based on the signal of the extruder, using the rated tension (adjustable, can better control the geometry of the material) to achieve synchronization with the extruder, automatic traction profile after extrusion of the profile, automatic Cutting profile and other functions; achieving the goal of improving product quality , saving manpower, and reducing costs。

details as follows:

Track:(Specially made of square steel and channel steel)→Tractor (precision machining)→Hydraulic device→Traction power(frequency conversion or server Driver)→Interface (touch screen display parameters, achieve numerical adjustment)

1. Track: Use cold drawn round steel as the main guide rail to limit the movement and rotation of the Y and Z axes. The walking wheels are two.

Group (3 in each group) 120-degree curved wheel, which can be precisely adjusted and highly reliable; using cold-drawn steel

Auxiliary guidance to limit the rotational freedom of the X-axis, ensuring smooth running of the traction trolley; rail frame and adjustable feet

The frame is made of steel, which guarantees sufficient firmness; the track is arranged to be biased to the high and low rails, and the main rail (round steel)

On the top, the auxiliary rail (square steel) is under the structure, the structure is compact, and the guiding is precise and reliable;

2. Traction car: The main parts are machined and manufactured to ensure the machining accuracy of each part and improve the whole machine.

Manufacturing precision, improve the reliability and running accuracy of the trolley operation;

3. the clamping mechanism: the pallet rises from both sides, to ensure that the return process does not scratch the aluminum, the bead curve design, compacted from

The lock is reliable, the pallet and the bead are controlled by the lower mechanism, and the hydraulic system is not used, which reduces the traction of the trolley.

Weight, reducing the brake impact during fast return; more convenient maintenance management; pallets and beading

The sequence of actions is implemented in the order of simple mechanical components, and because of the single-powered action, the general traction is removed.

The electric control box installed on the machine head removes the sliding line and the current collector, which greatly reduces electrical faults.

Reduce the quality of the traction head, make the control more flexible and the response speed is faster;

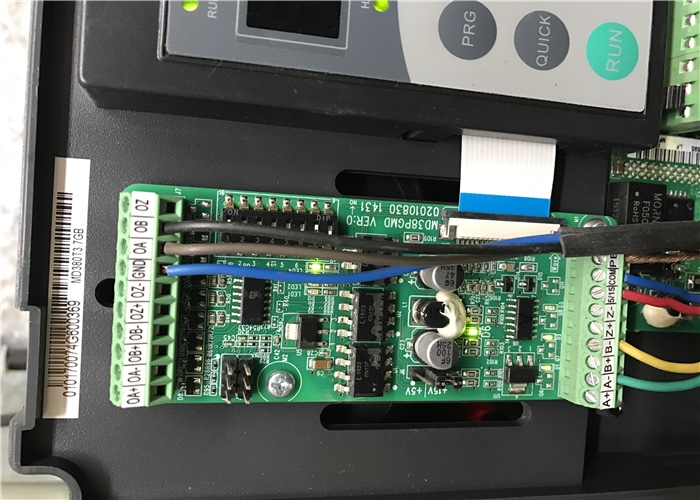

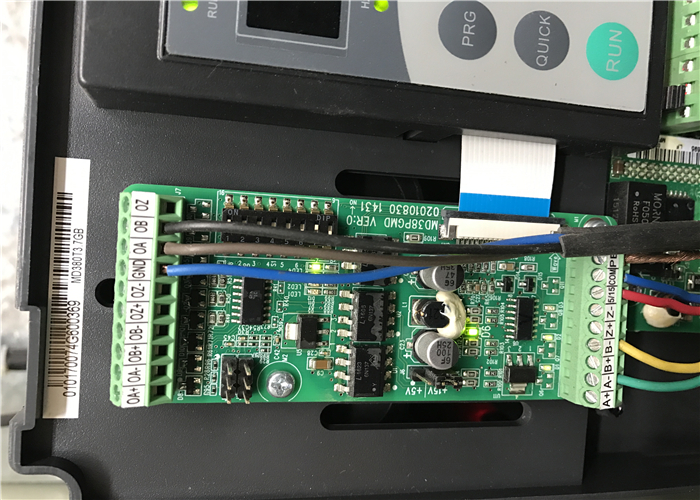

4. Traction power: use special frequency conversion motor to improve the controllability of speed and tension; use the constant torque output of the inverter to achieve the purpose of constant tension traction; segmental speed regulation to improve the control performance of the return speed of the tractor, reduce Backhaul impact failure;

5. Traction device: use the chain to drag the traction car and cooperate with the counting function of the encoder to ensure the accuracy of the position control of the tractor; the chain is supported by the wear-resistant PE plate slot to reduce the running resistance and noise;

6. Brake: Use the traction motor to brake the brakes, the brakes are more stable, and no mechanical brakes are used.

There is no brake life problem, the faulty parts are reduced, and maintenance management is easier;

7. Display: Display the main parameters and information, such as traction length and speed, using the man-machine interface, which is convenient for adjusting the length of the aluminum rod in time, improving the yield of the product, and facilitating maintenance and management;

8. Control: manual, automatic control, coordinated operation with interrupted saw, main machine and slide-out station, which improves the degree of automation and reduces the labor intensity;